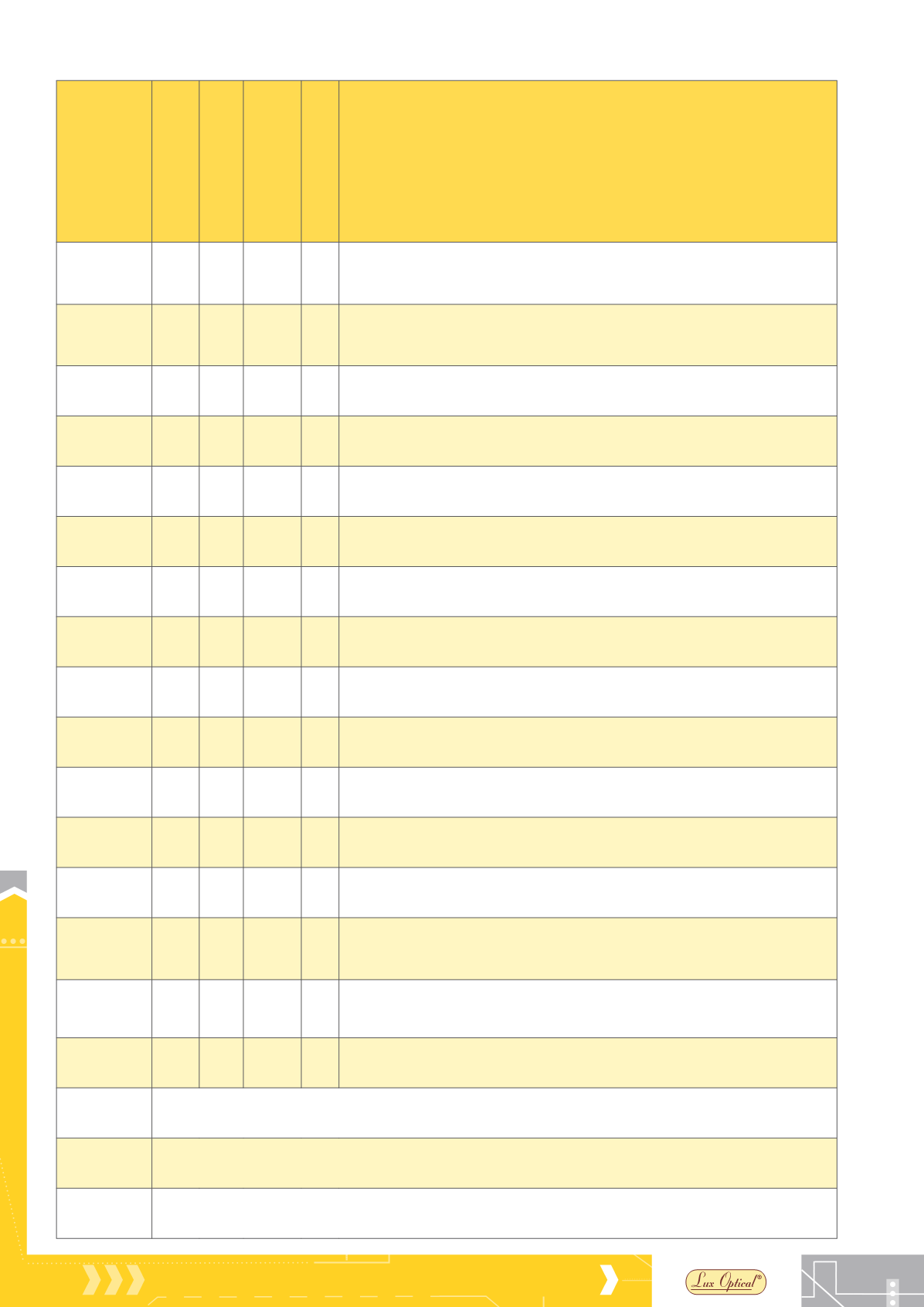

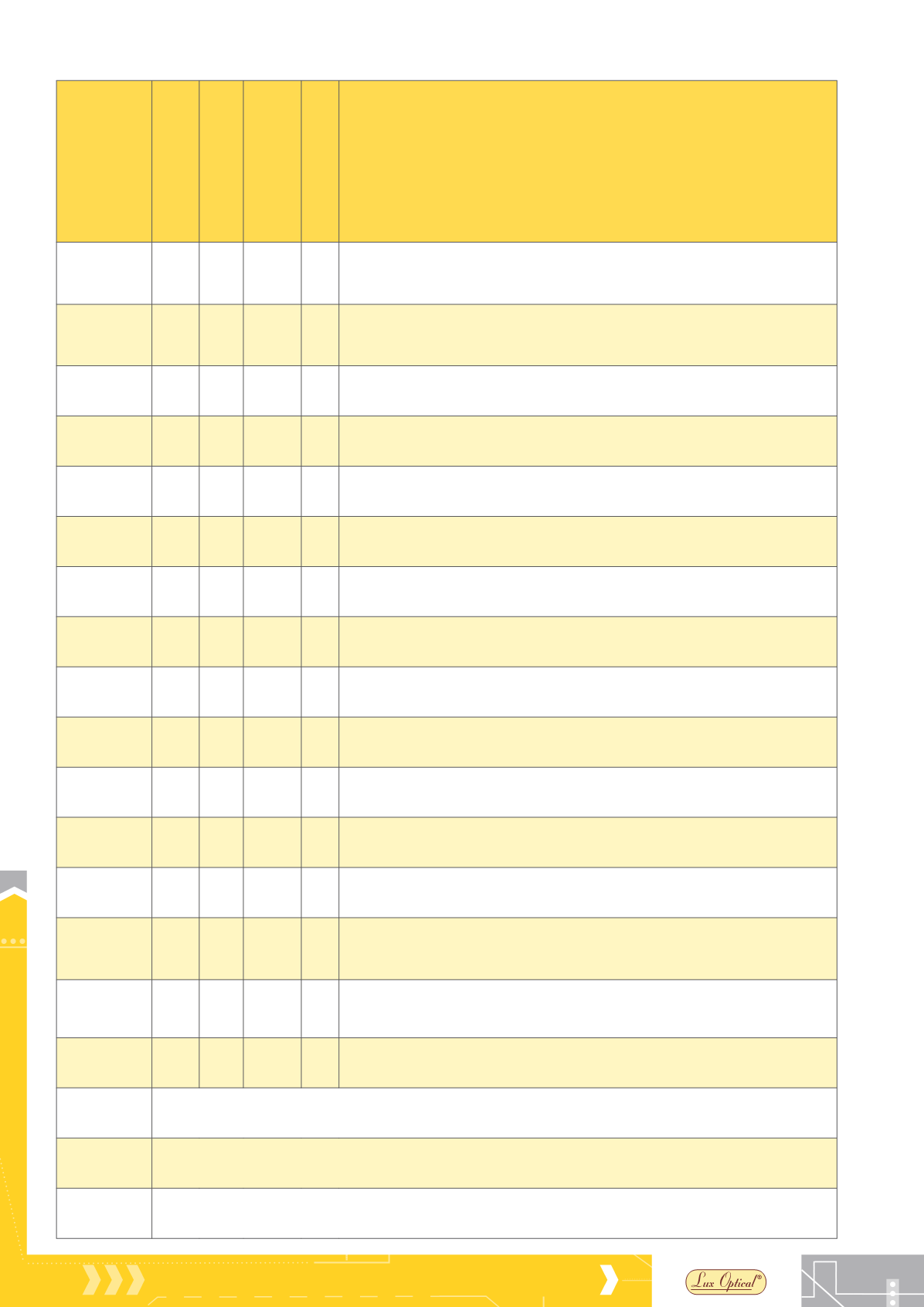

8

Lens color and scale number of the ultraviolet (UV) filter

Lenses color

Filter type and shade

EN 166

Transmittance

Standard

Absorption of light

EN1836

General property

Clear

2-1.2 90% EN 170 0

filter 99% of ultraviolet UV radiation up to 380 nm. General purpose lenses

with high impact strength capacity designed for use indoor or in weak

lighting conditions.

Yellow

2-1.2 89% EN 170 0

Eye relaxation, enhanced contrasts, recognizable colors and details in low

visibility + filters UV and blue light (up to 480 nm), suitable for night time

work and in overcast and misty conditions.

In-out

5-1.7 53% EN 172 1

Usable both indoor and outdoor (in strong sunlight and weaker lighting

conditions as well), realistic color perception, extra reflective coating

Orange

2-1.7 45% EN 170 1

Relaxes the eyes and enhances contracts + filters UV and blue light (up to

480 nm), function to help with focusing, e.g. checking surfaces

Bronze

5-2.5 23% EN 172 2

Protects against strong direct sunlight, enables good color perception with

alternating lights and shades, filters UV and blue light (up to 480 nm)

Smoke

5-2.5 17% EN 172 3

Enables good color perception even in strong direct sunlight,

filters UV radiation

Green

3-3 16% EN 172 3

Enables good color perception even in strong direct sunlight,

filters harmful UV radiation, alternative to gray lens

Red reflective 5-3.1 14% EN 172 3

Protects against blinding lights, reflective glare,

filters harmful UV radiation

Blue

reflective

5-2.5

5-3.1

20%

13%

EN 172 2

Protects against blinding lights, reflective glare, filters UV radiation, use for

waterside activities and driving

Silver

reflective

5-2.5

5-3.1

20%

13%

EN 172 2

Protects against blinding lights, reflective glare,

filters harmful UV radiation, use for outdoor activities

Dark gray

5-4.1 6% EN 172 4

Recommended for use in extreme and blinding lights, high mountains,

snowy and sandy terrains and on the waterside. Not to be used for driving.

Welding 1.7 1.7 54%

EN 169

EN 172

Additional glasses for welding (IR) or spot welding, protect against direct

sunlight (UV) as well

Welding 3

3 15%

EN 169

EN 172

Suitable for use in activities related to grinding, soldering and welding (IR),

protects against direct sunlight (UV) as well

Welding 5

5 2% EN 169

They protect against infrared (IR) radiation during gas welding and brazing

where gas flow rate (quantity of acetylene introduced into the flame) is max.

200 liters/hour and oxygen flow is max. 2,000 liters/hour for oxy-fuel cutting.

Welding 7

7 1% EN 169

They protect against infrared (IR) radiation during gas welding where gas

flow rate is max. 800 liters/hour and oxygen flow is max.

8,000 liters/hour for oxy-fuel cutting.

Cobalt blue 4-6 1.5% EN171

Protection against infrared and blinding light, yellow-orange radiation in

glass and metal industry, checking molding temperature in metallurgy

Reflective

coating

its miniscule metal particles help reduce the amount of light hitting the eyes in blinding lights

Polarized

coating

filters out reflections off smooth surfaces and glaring horizontal sunlight (snow, water surface, bright sand,

buildings with glass walls), helps improve feature and contrast perception

UV400

coating

filters out 100% of UV-A and UV-B and provides additional protection against blue light up to 400 nm

LUX OPTICAL

®

• GLASSES WITH TEMPLES